How to conduct digital remote monitoring during epidemic, direct a factory?

2022-05-25 Publisher: Number of views: 3445

2022-05-25 Publisher: Number of views: 3445

Reading guide

How to ensure the storage conditions of raw materials in the warehouse without supervision during the epidemic, How to realize remote start and stop of important loads when the equipment department cannot return to work, equipment alarm , Remote notification, How to realize comprehensive energy, fire control, Ambient temperature and humidity, Real time monitoring of equipment working conditions and other indicators, Data visualization, Analysis automation, Remote control!

Because of the epidemic, During the period of more than one month, Plant production equipment, lighting, Air conditioning equipment, Fire monitoring, pipeline supervision and control, water, electric, gas, How can I view it in real time?

Fire fighting in the factory, How can electrical disasters be known remotely?

How to achieve real-time warning?

During the sealing and control period, Raw materials in the warehouse have strict requirements on storage conditions but are unattended, How to supervise?

Xiaowa takes the global digital factory platform of a well-known food enterprise as an example, Explain how to solve the above problems.

one, Equipment monitoring

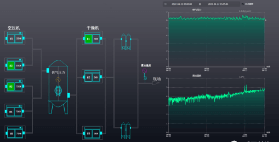

Air compressor operation diagram

Traditional factories need a lot of manpower to manage equipment status, Mobile personnel and scattered equipment are both a problem, In case of epidemic prevention and control, Unable to accurately manage equipment status and important parameters, The normal operation of production activities cannot be guaranteed.

Connected to the Internet of all things IMI Digital platform, Relevant data can be viewed in real time through the computer or mobile terminal, For example, the running state of the air compressor, Air supply pressure, etc, No resident site required, It can also guarantee normal production.

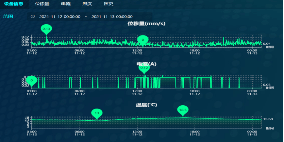

Equipment amplitude, electric current, temperature

As shown above, You can view the information of the current equipment through the platform, stay 11 month 12 day 0 Point to 11 month 13 day 0 Operation status of points, You can see the device information included, Displacement, electric current, Temperature and historical data, etc.

According to the data obtained, The abnormal jitter of the device can be found remotely through the platform, Abnormal conditions such as high operating temperature of equipment, Improved enterprise equipment management, Efficiency of supervision. Especially during the epidemic, There are not enough people to look after so many equipment, Even those working in related fields cannot enter the factory for work, IMI The platform can also configure SMS through the system, mail, Telephone, Automatic control and other different alarm and processing methods. Ensure the safety of plant and equipment.

two, Environmental monitoring

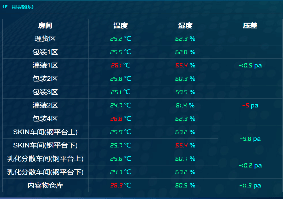

Environmental monitoring system

The above figure shows the environmental monitoring data of each production area of a well-known enterprise in Shanghai, The temperature in the warehouse can be seen in real time from the platform, humidity, differential pressure.

The environmental conditions of each zone play a very important role in the whole process, If too much exceeds the standard, it will lead to decay and deterioration.

Through us IMI After monitoring and management of the platform, According to the environmental conditions of each room, When the allowable range is exceeded, the system will automatically turn on the fan, Exhaust. Ensure the freshness of products in each area.

But if the warehouse managed by digital means is not used, So during the epidemic, The products may all break down, The loss will be millions.

three, Energy monitoring

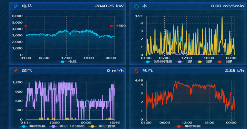

Integrated energy monitoring

In addition to equipment and environment, Energy is the lifeline of production, The above figure shows the comprehensive energy monitoring of the whole plant, Including water, electric, gas, Four energy sources of heat. It is different from traditional companies that only produce single electricity or some kind of energy, We can manage electricity in one platform, water, gas, Heat and other traditional energy sources, PV can also be managed, New energy such as energy storage.

Fine control of energy in a large screen, Unattended during the outbreak, The employees of the equipment department can be isolated at home to ensure the stable energy supply of the whole plant, Find problems in time, real-time processing.

four, Safety monitoring

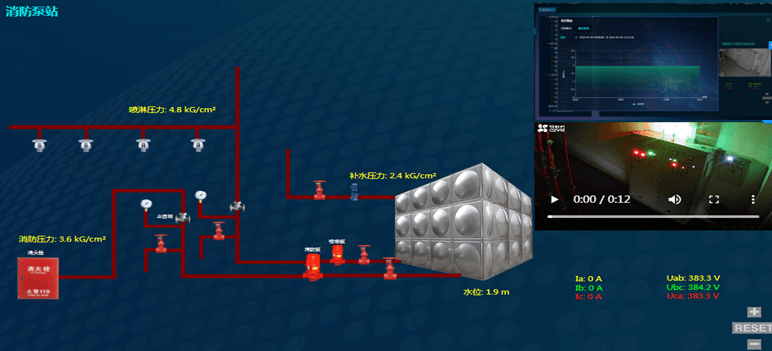

Fire monitoring

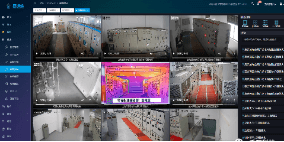

Video surveillance

production safety , Fire safety is the top priority of enterprises. At ordinary times, the fire engine will have false alarm, However, artificial management may lead to untimely discovery, Problems such as untimely handling. Through us IMI Internet of things platform, It can be connected to various fire engines, Haikang, Dahua, Fluorite and other cameras, Realize real-time notification of security alarm, At the same time, the camera near the alarm point can also be accessed through the platform, Quickly locate the fault point, Avoid false positives, Underreporting.

Except for ordinary cameras, The system can also be connected to the infrared thermal imaging camera for temperature sensing, As long as the equipment temperature exceeds the set threshold, it will alarm, Foreign matter intrusion can also be accessed, Smoke sensing camera, During the unattended period of the epidemic, Especially important.

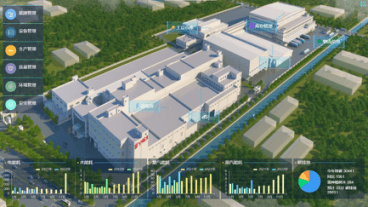

One screen view of the whole plant

adopt IMI Internet of things digital platform, Truly connect everything at one end, One screen view of the overall situation, I. whole process of network management, One person to the whole post. Real realization "Devise strategies among , Successful in distant " .

There is not a single outbreak that will not go away, No spring will not come, Shanghai's data continues to improve, It's not far away.

365

365